The development history of DH quick piles and the application of rapid construction in the industrial sector

Li Shengnan / Deputy General Manager of Dehan Wisdom Technology Co., Ltd.

date: 2016-12-19

Note: The readers shall know that most content of this paper is translated from original traditional chinese version by software. Foreword

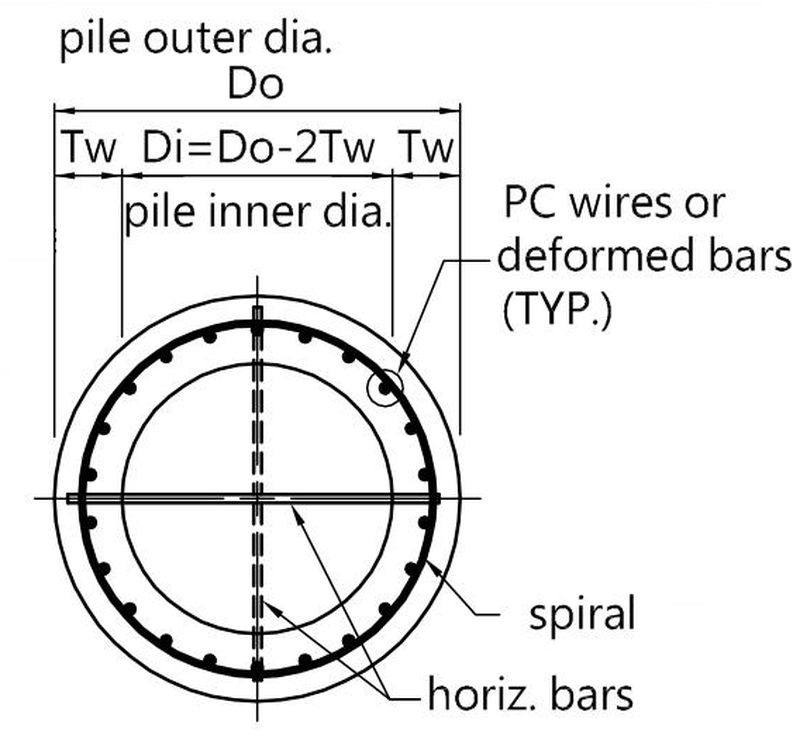

DH advanced quick prestressed piles (hereinafter referred to as DH quick piles) are the pre-stressed piles developed by Dehan Company, which have improved the lack of traditional PC/PHC piles for decades and have more advantages. Most of the ideas in this article are actually described in our reference standard chart (please download from the download area of the official website http://www.dehantech.com), but the engineering drawings are often deep and difficult for the general public to understand. Therefore, the text and length of the vernacular are further explained here.

Dehan has a lot of exclusive technologies in pre-stressed piles. The DH quick piles mentioned in this article are limited to the first-order piles of Dehan Company (internal product No.: DH PLV1 type); other types of piles The technical content will be introduced later.

▲Figure 0-1: DH quick pile of 1st generation (2012), vent hole on the side wall (left)

Figure 0-2: DH quick pile of 3rd generation (2016) , with venting holes above (left)

1. The advantages and development of DH quick pile

DH quick pile (first generation) is a new generation of pre-stressed piles developed by Dehan in 2012 (Fig. 0-1). In 2015, it has developed into the 3rd generation (Fig. 0-2), which is more than traditional PC/PHC piles have engineering advantages such as short construction period, high safety, low integration cost and easy inspection. The following will introduce the corresponding developments of DH quick piles by introducing several advantages of DH quick piles:

1.1 High security:

In fact, this is the original improvement motivation of the DH quick pile.

When we saw that the traditional PC/PHC pile was used in the "pile head treatment" after the construction of the site, the "secondary core clearing" process was used, and a large machine was used to directly drill a hole of about 2m depth on the pile head. (Fig. 1-1), the cement slurry in the inner hole is mixed with dry sand but not properly removed (it is also difficult to completely remove it) (Fig. 1-2), and then placed in the anchor cage anchored by the pile head. , refilling "expansive concrete" into pile-filled concrete.

Figure 1-: 1 traditional planting pile: secondary core processing and machine tools

Figure 1-2: Traditional planting pile: the inner wall of the pile after the core cleaned (right)

Figure 1-3: Traditional planting piles: pile heads placed in steel cages and filled core concrete

The expanded concrete used as the core of the pile head is used to make the cored concrete in the inner hole of the pile head expand slightly after drying and hard to "support" the PC/PHC pile wall concrete, and generate friction to resist the upper structure. The upward pull that is transmitted. However, the construction of piles in Taiwan's construction sites has been subdivided into sub-contracts. The small subcontractors of these "secondary core clearing" processes have low profit margins, and it is impossible to clean the internal holes of the pile heads again with industrial-grade high-pressure water jets. It is also difficult to ensure the durability of the inner hole friction. When required, it is generally only used with higher pressure water (non-water knife is very similar to car wash high pressure water). It is slightly flushed (some even high pressure water wash is not applied), this It is only possible to clarify the attached mud slightly. When the work is completed after the completion of the drilling (Fig. 1-2), which may cause the tensile force of the pile-filled concrete section to be degraded or invalid, which seriously deviates from the design. The ideal assumption of the engineer. Therefore, the DH quick pile is designed with a "hollow pile head" and a "multi-layer pre-embedded horizontal reinforcement" in the pile head as a joint interface with the upper structure (Fig. 1-4). This design improves the frictional form of the bore of the pile in the traditional pile (which may only withstand about 20 tons), and can withstand a stable tensile load of more than 175 tons (Figure 1-5) [1] (Note: The tensile force of the pile-core filling section is not the pile pulling force capacity. So don't misunderstand it).

Figure 1-4: Hollow pile head and horizontal reinforcement of DH quick pile

Figure 1-5: DH quick pile pull test [1]

Of course, the practical use of the piles in engineering is still the main function of vertical loading. The design of the tension load is not the keypoint. In practice, there is no need to design excessive tension capacity. However, the tensile load of 100~300 tons of DH quick pile inner core filling section has also met the requirements of design engineers. In the example, in the collapse of the building in China in 2009 (Figure 1-6), we can also see some cases where the PC/PHC pile is damaged due to the tension [2].

Figure 1-6: PC/PHC piles damaged by tension during building collapse [2] The new design of this DH quick pile head also gave us a lot of sense of accomplishment, because we completely changed and broke through the important blind spots of the pile-pushing technology introduced from Japan in the past 30 years.

[Increase the anti-microseismic capability of PC/PHC pile heads]:

In addition to the increase and stability of the load force in the bore of the pile head, there is another advantage mentioned: increasing the resistance to micro-shock of the PC/PHC pile head. This is because the DH quick pile changes the way the pile head is combined, so that the traditional combination of the friction between the concrete and the pile wall is changed to the shear anchoring combination method depending on the preset horizontal reinforcement of the pile head, which makes the DH quick pile head. The combination of the types jumped to the mechanically coupled structural joint type.

DH quick piles is better than traditional PC/PHC when the structure above the DH quick pile must withstand high frequency vibrations (for example, mechanical equipment with high precision requirements) or must resist micro vibrations (such as high-tech factories). Anti-vibration ability, This is in addition to the increase in tensile strength and shear resistance of the DH quick pile head, because the core-filled concrete of the traditional PC/PHC pile head will be loosened due to the long time of use, but the DH quick pile will not loosen. It is the exclusive technology of DH quick pile "the pile head never released" [3].

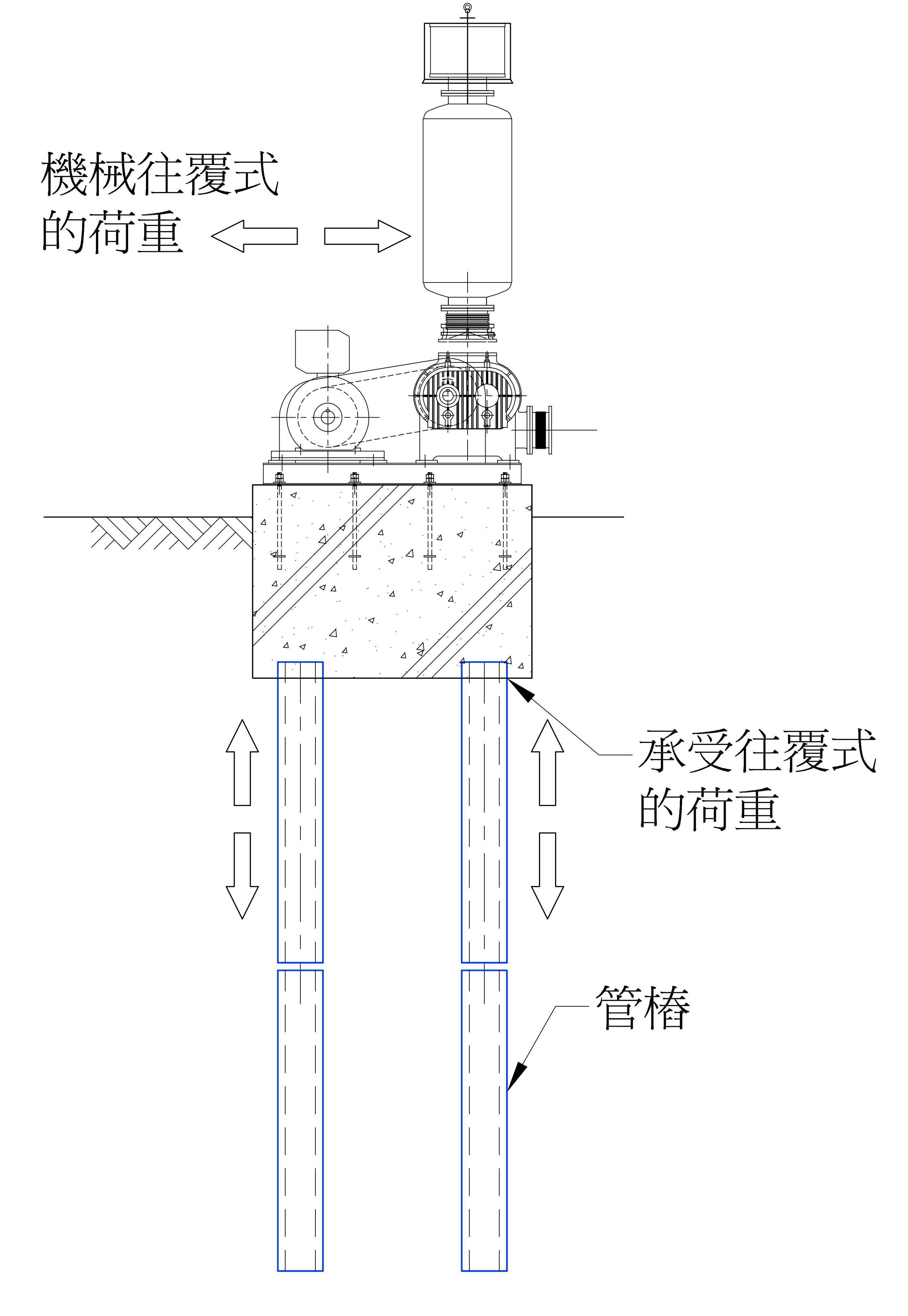

If the pipe pile is designed to support highly vibrating machinery (such as heavy-duty air compressors, etc.), the vibration load of the equipment is transferred to the concrete base by the foundation bolts and then to the lower pile support. These repeated vibration loads will cause additional dynamic load on the pile-filled concrete, and the repeated interface friction will reduce or reduce the frictional strength between the core-filled concrete and the pile wall. In contrast, it will bring additional foundation. Vibration, degrading mechanical life. Buildings that accept repeated wind loads will also have similar effects on the pile foundation (Figure 1-7) [4].

Figure 1-7: Pile foundation with reciprocating load, the pile joint is also subjected to reciprocating load [4] The new pile head design of the DH quick pile can make the precision machinery last longer, reduce maintenance and increase the home rate, or ensure its precision and increase the yield of the product in mechanical use. For some industrial mechanical operations, Or even precision industrial grade machine operation is very helpful. These industries are commonly found in Taiwan's petrochemical and electronics industries. Since the DH quick pile does not change the shape of the pile, in the case of the outer diameter and the same pile length, the compressive bearing capacity of the pile is not increased or decreased, which must be understood by the reader. (Note: This point may be changed in other pile technology of the DH company)

1.2 Low integration costs: Basically, the concept of PC/PHC pile cost is: total cost

= factory fabricating cost

+ site construction cost

+ site pile head treatment cost

+ other added costs (such as manpower)

+ negative costs (such as duration)

Due to the introduction of new technology, the DH quick pile will increase the cost of prefabrication in the factory, which will cause the outside world to have higher unit price doubts. In fact, everyone who works in engineering knows that the completion of a project is often done by a number of different types of work. The job interface is numerous (and waiting to be delayed), and many overlapping resources are wasted.

DH quick piles have moved many of the workloads in the work of planting piles to the prefabrication stage of the factory, which is equivalent to trying to "factory" the civil work. In the production of DH quick pile heads, we must also add the main parts such as the lower dam and the horizontal ribs, which will cause some delays in the production process of the pile factory, and the cost increase is inevitable. In addition to the completion of the PC/PHC pile steaming, it is necessary to install the snorkel and the upper cover of the pile head to form our "hollow pile head". Although there are not many materials, the labor of assembling these labors is cost. These are all the costs of making DH quick piles.

However, when the DH quick pile construction (site) are completed, the work of clearing the core of the secondary core can be omitted; at the same time, other work types can be immediately added to the work sequence, and the cost of the overall integration is not high. When the civil work is carried out on the construction site, the most cost-saving, but few people will count the cost of the process interface, it is a pity. The development of the DH quick pile is to take into account the cost integration of this part, which is to integrate the "time cost" in addition to the traditional cost of calculating only man-machines. (Note: Civil engineering work is very time-consuming but the pile work is the most time-consuming work in civil engineering)

The "profit" based on the contractor is closely related to the "cost". Of course, it is also related to our technical interests. Let us skip the in-depth description of this part. (Note: I don’t talk about money in this article. Interested friends can talk directly.)

1.3 Short construction period:

The DH quick pile moves many of the workloads in the work of planting piles to the prefabrication stage of the factory, so it can save a lot of construction period and labor during the construction phase. Planting piles at the construction site is a rather time-consuming task, and in the implementation of the piles, almost all the work in the construction site cannot be carried out, and all the man-made materials are "waiting". Except for the construction period of the pile-pile construction (about 15 piles per day), even if the pile is completed, the construction site still has to wait for a period of time (about 14 to 28 days) to give the pile-hole cement slurry a certain strength; The core clearing hole also requires process waiting (about 30 piles/day), and the waiting time between the work items is more time-consuming. These messy work items are all time-consuming.

In the development of DH quick piles, "a large amount of savings during the construction period" is the mainly advantage that was once again discovered in the later stage, which is the biggest weapon of the DH pile. This period makes DH quick piles out of the stage of "sale pile products", and further merges "sale time" to customers; of course, the aforementioned high quality is also included, which is not possible with traditional PC/PHC piles.

The engineering people know that "as long as the civil engineering work can be rushed up, other work can be rushed up." This definitely means "schedule." In civil engineering, "underground work" is the most time-consuming. If it is based on PC/PHC piles, it is the most time-consuming process of planting piles.

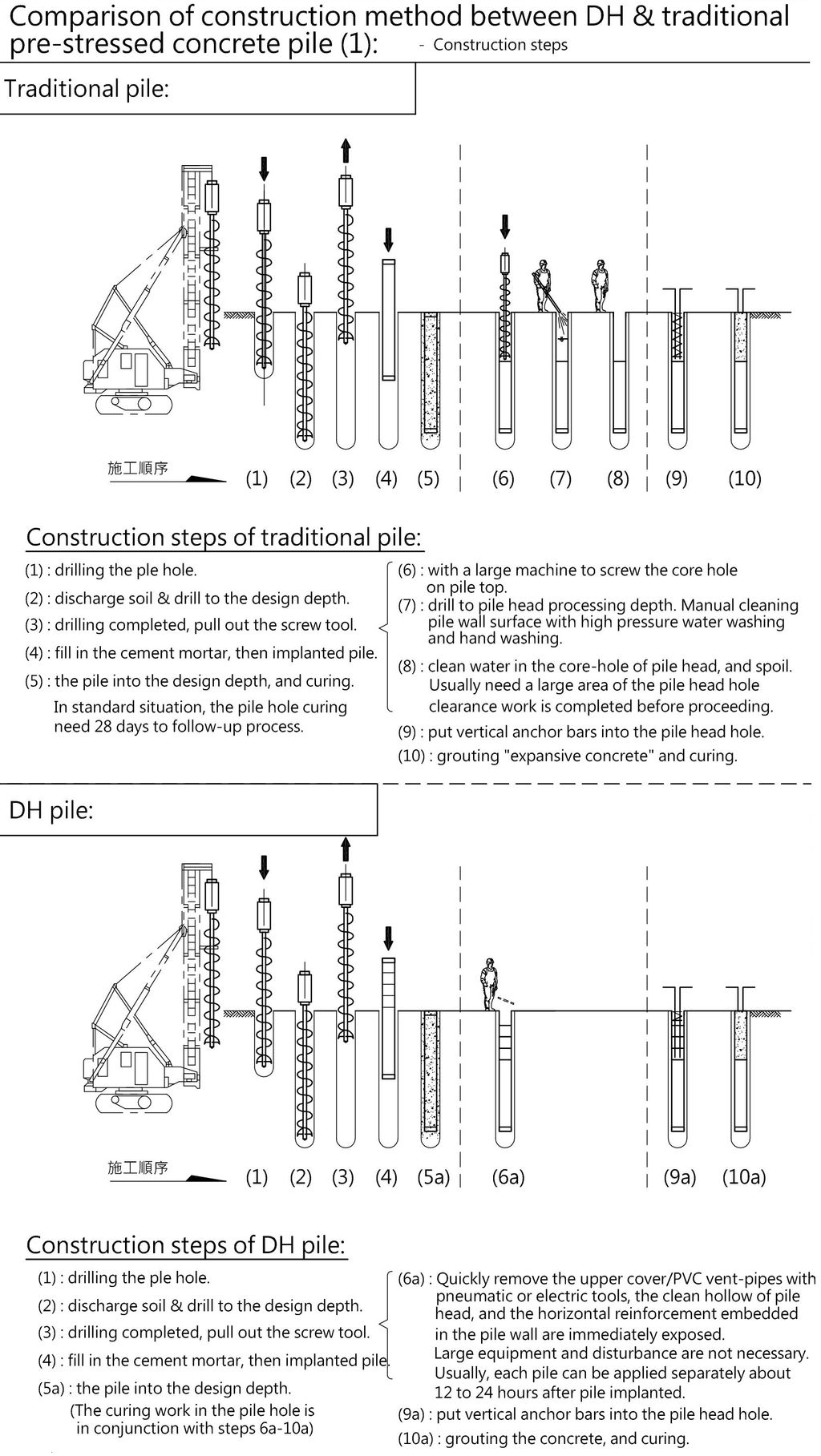

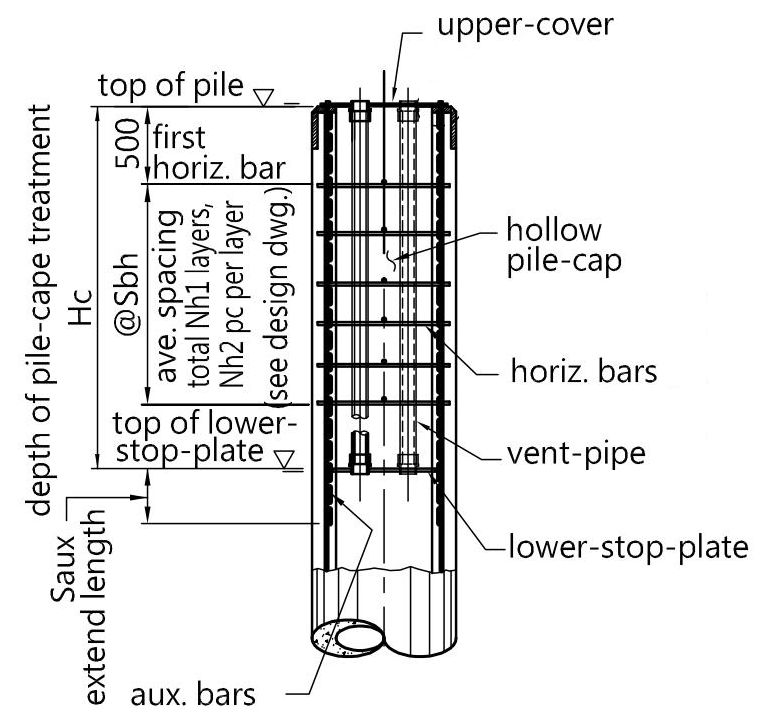

Due to the design of the DH quick pile hollow pile head, there is a difference in the pile construction of the DH quick pile and the conventional pile pile during the pile construction (Fig. 1-8). The hollow pile head allows the DH quick pile to be opened at the time after the soil layer is implanted, and the subsequent civil engineering process is connected. In Figure 1-3, we can clearly see that the main difference between the two is in the “process after the foundation pile is established”. The upper cover of the hollow pile head is designed to be easily opened with a manual or power tool (Figure 1-9). When the upper lid is opened, the unique design of the DH hollow pile head (Fig. 1-10) is revealed, and the preset horizontal ribs are lightly visible (Fig. 1-11). The pile heads of the subsequent civil work are anchored to the steel cage (vertical reinforcement) and can be inserted (Fig. 0-2). After filling the cored concrete, the pile work is completed (Figure 1-12).

Figure 1-8: Comparison of DH quick pile and traditional pile pile construction

Figure 1-9: Opening of the DH quick pile (manual example, simple opening)

Figure 1-10: The hollow pile head exposed after the opening of the DH fast pile

Figure 1-11: Preset horizontal ribs of the DH fast pile

Figure 1-12: DH quick pile filling core concrete (schematic)

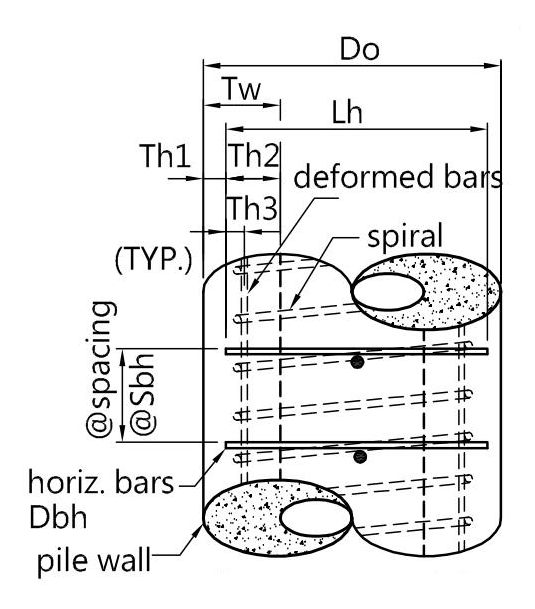

Because the DH quick pile can make the cement slurry in the pile hole not enter the hollow pile head part of the pile top during the construction of the pile, after opening the upper cover, the preset horizontal rib and the clean hollow pile head are exposed, and the core is provided. Required for concrete infusion. The tensile design of the pile core filling section of the DH quick pile is directly embedded in the concrete of the pile wall by the preset horizontal ribs, and combined with the core-filling concrete, because the friction between the core-filled concrete and the pile-wall concrete is not required, It can be used with ordinary concrete without using expanded concrete.

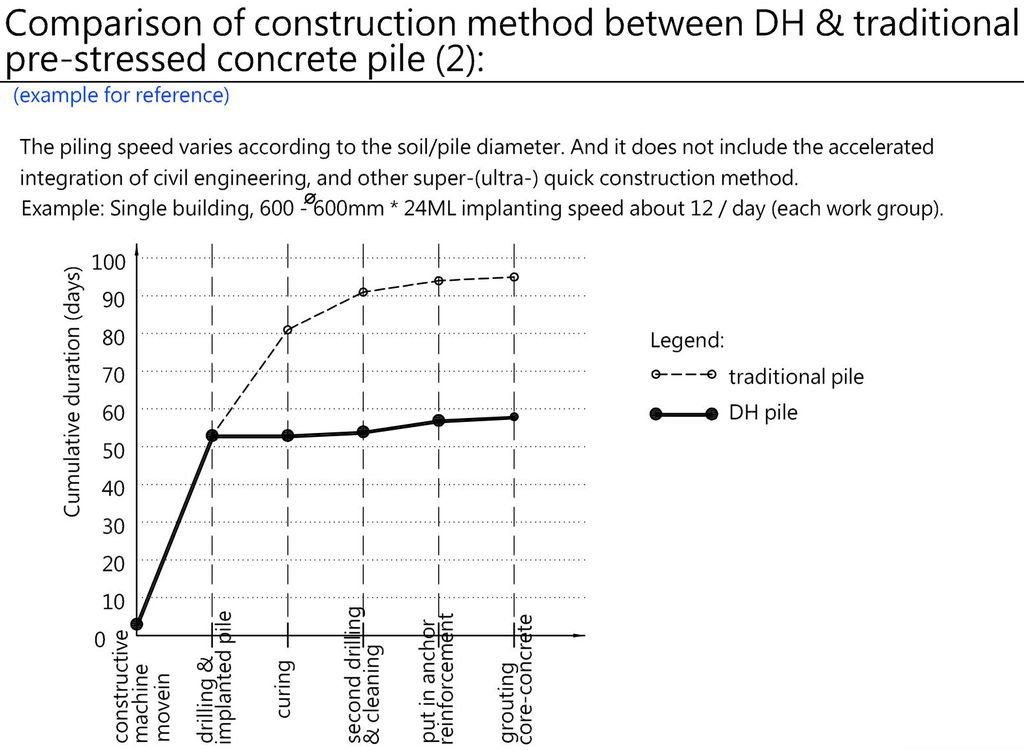

Figure 1-13: Comparison of construction period of DH quick pile and traditional pile (single process)

Figure 1-14: Comparison of construction period of DH quick piles and traditional piles (process integration)

Compared with traditional piles, DH quick piles can be completed with less time (Figure 1-13) because it saves a lot of processes, which highlights the advantages of DH quick piles. Further work-process integration will have a better time advantage (Figure 1-14), which will be described later (suitable for larger and larger-area construction cases). In the construction of the DH quick pile, we used the pre-fabrication procedure of the pile factory to add the presets of "hollow pile head" and "shoring head horizontal rib". When the construction site is constructed, the pile hole cement slurry can pass smoothly without filling up. The inner hole of the pile head. After the pile is completed (after 24 to 48 HR), the upper cover of the DH quick pile can be opened, and the pile head processing construction process of the cored reinforced concrete can be quickly carried out. This is a major feature of the DH quick pile, which can make the piled pile and the basic civil work work in a coherent manner, and there is no time to delay (of course, it does not need to be so urgent when it is officially constructed). The industry is highly efficient, and the investment recovery time is as short as possible. It is conceivable that the compression of the DH quick pile is urgent for many industrial owners.

The above is our company's "DH quick piling method" (Figure 1-8). Dehan also further developed the "DH super-quick piling method" and "DH ultra-quick piling method" for shorter construction period. Due to space/time limitations, we will have the opportunity to introduce it later.

1.4 Easy to inspection:

The completion of the foundation pile project mainly includes three: (1) factory prefabrication of the pile (including transportation), (2) construction of the pile, and (3) pile head treatment of the pile. Normally, everyone's work on piles is concentrated in the first two items, while the last integrated work is neglected, often classified as a scope of civil sub-contractor, rather than scope of piling sub-contractor. The construction period of traditional pile construction has been for a long time, and the piling sub-contractor is often reluctant to go back and deal with it, which may result in the lack of work connection.

- Factory prefabrication of foundation piles: In fact, DH quick piles have not changed a lot of traditional PC/PHC piles. The factory inspection method is still based on CNS 2602 standard, plus direct supervision of production and factory inspection.

- Piling construction: DH quick piles are almost the same as traditional piling methods in construction of piles at construction sites.

- Pile head treatment of piles: The main difference will be between the secondary core clearing (traditional pile) and the top cover (DH pile). When the traditional pile-growing method is used to clear the core, the cleaning degree of the inner hole will be greatly caused by factors such as the case (pile diameter and inner hole depth), the seriousness of the construction work, and whether there is high-pressure water flushing. The difference (Figure 1-2) often makes it difficult for supervisors (or owners) to judge whether they are qualified or not.

The design of the hollow pile head has been created at the time of factory pile production. The hollow pile head is formed by the preset lower dam, the PVC vent pipe and the upper cover, so that the pile hole cement slurry does not flow. After the cover is opened, the "clean hollow pile head" is exposed, which is easy for the supervisor to visually inspect and the quality control is quite easy to implement.

Contracting the construction company (or small to the sub-contractor/workor class level) to seek quicker and cheaper is the convenience and profit, but also the unwritten routine in the current engineering market, the supervisors can not be so sloppy. Engineering often requires consistency of materials and construction quality, minimize differences, to facilitate the implementation of quality control, to ensure the quality of finished products after construction; when the materials are equivalent, the construction method is the source of the difference. In the traditional pile-pile construction, the secondary core drilling process often causes excessive differences and should be eliminated or phased out. This is the reason why we develop the DH pile-pile method, and it is also the advantage of the DH pile-pile method, so that the piles at the completion time The quality of the pile head can maintain considerable consistency and is far superior to the traditional pile-grilling method. (Note: Dehan also extended this significant advantage to the later application of DH 6th-level piles)

1.5 Reduce risk:

This is related to Dehan's DH 5th and 6th-level piles. Let me talk about it later.

2. The new concept introduced by DH quick pile in engineering

The advantages of DH quick piles and the differences from conventional PC/PHC piles are described above. In the process of our research and development, it is also applicable to introduce some new ideas in engineering:

2.1 Increasing the proportion of assembled work: reducing work on the site, increasing factory work, and introducing manufacturing concepts into the engineering industry

Due to the large difference in the environment of the construction site, the terrain/weather/wind are easy to be affected; and the workers are also susceptible to the corresponding impact; the workers are mostly temporarily grouped, the stability is poor, and the skill training varies greatly. All of these will affect the quality of the finished product. DH quick piles are required for the various processes in the traditional planting work, and are moved from the construction site to the factory in advance, through the equipment in the factory (such as movable cranes, automatic netting machines, etc.), production lines, and more trained workers. Class personnel, and even quality control inspection operations, can improve the quality and increase the stability of the finished product. It can also shorten the time (such as high-temperature steaming to accelerate dry and hard), and good operation can even reduce the overall cost.

The current project also pays attention to increasing the proportion of assembly work, which is used to make the quality better and the construction period shorter.

Most of the assembly work in the project is in the superstructure, such as beam/column/slab/wall, or even the bridge column in the bridge project; but it has not been seen in the foundation pile, except for the tradition. Beside the prefabricated PC/PHC pile, the DH quick pile further combines the PC/PHC pile with the upper base structure and performs a quick combination of similar assembly methods.

[Introducing manufacturing concepts into the engineering industry]: After a century of evolution, many of the manufacturing concepts of manufacturing are commendable, especially from the factory-manufactured manufacturing of Henry Ford's automotive production line processes; and, like the "JIT System" (Just In Time) at the end of the 20th century The concept of "product just in time" and "zero inventory" has also helped the rise of large factories such as Toyota, and greatly improved the management technology of various supply parts of the production line.

On the other hand, in the construction industry, especially in the construction industry where construction is carried out on the construction site, many concepts still remain in the production methods of the last century, relying heavily on labor, measuring stakeouts, formwork, steel, concrete, etc. Need to be "manual", except for some mechanized construction tools. Of course, this is also related to the characteristics of the construction industry, that is, the method is so "technical."

In the technical improvement of DH quick piles, we focus on the interface between pile and foundation. The former is generally classified into the geo-field, while the latter is the structure field, and the interface between these two is somewhat blurred. Taking the PC/PHC pile as an example, this interface is in the "piling". Implanted piles were sourced from Japan until the 1960s. The earliest application example in Taiwan was in 1988 [5]. In the past 30 years, Japan and Taiwan have not had a better way to solve the details of PC/PHC pile head treatment, and can only be used to solve both the "expanded concrete" and the "secondary core bore depth". However, both of them are only inaccurate methods, and it is very easy to have a large number of variations with the quality of the construction workers and the professional/cautiousness of the supervisors (Figure 1-1, Figure 1-2). The degree of mechanical removal of the inner hole during the secondary core drilling, the degree of manual removal, the degree of high-pressure water cleaning of the inner hole wall [6], and the removal of residual water are all pre-processes that greatly affect the processing power of the pile head, especially It is a high-pressure water cleaning process (about NT$200-300/hole) deep in the inner hole wall. It is said that it can only be cleaned to a depth of about 1 meter. For deeper cleaning, it is almost impossible for the construction site to reach, unless it is impossible. It is the use of "industrial waterjet treatment", which is more related to the processing cost (about NT$3,000 to 5,000/hole). This cost is not borne by small subcontractors, and it is almost impossible to conduct inspections.

The DH quick pile was made. We have moved most of the processes in the pile head treatment to the "more reliable factory". After the piles are planted on the construction site, the inner holes of the clean pile heads are specifically presented as eye-catching. Even in Japan, this technology is not provided. The materials (or parts) of PC/PHC piles, core-filled concrete, civil foundations, and other parts can be concentrated in the construction site in the shortest time, or the time of stay can be minimized, similar to the production line. The concept that all parts can arrive in time. This has completely different progress from the traditional work thinking in the land management, employment management and sub-contractor management of the construction site.

2.2 Easy-opening type of pile head treatment processing

Due to the large changes in the environment of the construction site, the terrain/weather/wind and rain are easily affected. To meet the requirements of Section 2.1 of this paper, a “clean hollow pile head” must be used to support the subsequent processes. Traditionally, the appearance of the bore in the pile head has to rely on the secondary core process (Fig. 1-1); the DH quick pile creates the "easy-opening pile head treatment process" to make it easy to practice.

The DH quick pile cover can be easily opened (Figure 1-9). The large opening of the construction site uses a quick opening of the pneumatic/electric wrench (this is related to the number of covers and the degree of concentration. If a small amount of cover is used, the manual method is adopted). Once the top cover of the pile top is opened, the hollow pile head is exposed (Fig. 1-10). After the preset PVC vent pipe is taken out (Fig. 1-11), the preset horizontal ribs in the hollow pile head are immediately presented. This hollow pile head is used to infuse core-filled concrete (including steel cages) and is used to undertake subsequent civil foundation processes; of course, the two can also be combined.

This is DH's original "easy-opening pile head treatment process", so that the pile-pile process can be quickly connected with the civil engineering process. Of course, the mechanical bonding force is absolutely better. (Details will be introduced later)

2.3 Creation of hollow pile heads

To meet the requirements of Section 2.2, the hollow pile heads must be pre-assembled in the factory (Figure 2-1) before they sent to the construction site. The hollow pile head of the DH quick pile has three main parts: the lower dam, the vent pipe, and the upper cover (Fig. 2-1) (Note: The preset horizontal reinforcement has another function, but it is not the requirement of the hollow pile head). These parts must be assembled before the piles are shipped from the factory, so that they can be used in the construction site to immediately cooperate with other processes.

Fig. 2-1: Composition of DH quick pile hollow pile head

Fig. 2-2: DH quick pile hollow pile head exposed after opening

Before the fabricating of PC/PHC piles, the assembly of steel bars and spiral ribs (commonly known as netting) has already been the work of automated electric welding. Before the concrete is fed, the lower dam of the hollow pile head part must first be fixed at the design position. After the concrete is fed, the pile mold is rolled and centrifugally formed, and after the high temperature steaming, the PVC snorkel assembly and the upper cover are assembled. Thus, the DH hollow pile head is formed.

2.4 Switching to the wall of the pile to replace the tension of the pile core

The design of the pile head preset horizontal reinforcement is the most original source of creation for the DH quick pile. We have seen the combination of the "unreliable" pile heads produced in the traditional pile-grilling method, and the horizontal reinforcement have been pre-buried into the pile-wall concrete before the piles are delivered in the preset way. The shape of these horizontal ribs is also different. From the 1st generation (2011) , the "U" shaped bar (the best in strength), the 2nd generation (2013) of the "double L" shaped steel bar (the second best in strength), the 3rd generation (2015) of "straight" shaped steel bars (the worst in strength), the current horizontal reinforcement design is 6 layers, each layer of 2 steel bars intersect, with 24 concrete joints, both simplified and sufficient (Figure 2-3, Figure 2-1, 2-2).

Fig. 2-3: Horizontal ribs of DH quick pile hollow pile head

In addition to the reduction and simplification of production costs, we also consider that PC/PHC piles, which are mainly used for vertical pressure bearing, do not need to bear excessive tension, and simply extend straight into the concrete of the pile wall with straight straight steel bars. That is, it can produce a tensile strength of 100 to 300 tons. If there is a need for a higher core tensile strength, it can be easily improved by changing the number of layers of the horizontal ribs and the number of each layer. The factory is also easy to manufacture, and there is no trouble in the construction of the site.

After the pile is completed, the cover on the construction site can be opened, and the pre-assembled vertical steel cage (anchor reinforcement) can be inserted into the hollow pile head, and then the core concrete can be poured to complete the pile head treatment process. It is worth noting that in the DH quick pile, the core-filled concrete only uses ordinary concrete (210-280 kg/cm2) instead of the traditional expanded concrete.

- The additional cost of the expansive concrete, whether it is added or the right amount, often depends only on the conscience of the construction contractor (or subcontractor) and the ready-mixed concrete industry, and there is no disposal in supervision and inspection. The quality of concrete placed on the ground is also poor.

- After the dry concrete is dry and hard, the strength is formed and the volumetric micro-expansion effect is difficult to estimate. After many years of use (for example, 20 to 40 years), whether the expansion effect is affected by the weathering of the concrete is difficult to estimate, and these may be The loss or loss of the friction between the core-filled section and the pile wall will be difficult to prevent if there is unpredictable tension (refer to Figure 1-6).

- After using the DH quick pile, the tensile strength of the pile core section has been replaced by the shear resistance of the preset horizontal rib embedded in the pile wall concrete. This force is more stable than the conventional friction. It does not detract from the need for the expansion concrete, so it is enough to use only ordinary concrete in the DH quick pile.

[Design of B-type DH quick pile]:

In order to make the DH quick piles more conservative and do not want to change the traditional pile head combination, we also designed the B type DH quick pile (PLV1B type). This type B DH quick pile retains the design of the hollow pile head, but does not design the horizontal reinforcement of the pile head, but relies on the combination of the traditional expansion of the core-filled concrete and the pile wall. Although it is not too advanced, it can be the intermediate step from the traditional pile to the DH quick pile.

Readers who are interested in research can download our sample drawings (autocad and pdf files) from the Dehan website.

2.5 Changing the job interface problem during construction and the short-term construction period of challenging pile work

After the DH quick pile has been mechanically innovated (see para. 2.1 to 2.3), we find that it is not easy to be favored by the owners. After scrutinizing the reasons, we found that the DH quick pile is good, but the mechanical improvement is not the focus of the owner. The consultants/engineers who undertake the design case do not like the "new things", although the DH quick pile looks It is "more solid and reliable".

After careful analysis, it was found that "cost, construction period" is the most important concern of the owners, especially the "work period", mainly because the huge amount of investment will create financial pressure when the plant is built, and the delay in the construction period will affect the start of the factory, which will result in products. The DH quick Pile developed a "compression schedule technology" to meet the pressure and demanding owners.

In addition to the period saving of the DH quick pile, by integrating the interface between the various types of work, including the pre-subcontractore gap (waiting for work shifts) between the types of small subcontractor (or even the work shift), entry, operation, cleaning and departure, etc., are wasting cost/period of main-contractor (also the owner's construction period). In Fig. 1-8, 1-13, and 1-14, the reader can see the details of the integration and the savings of the duration, and more importantly, the individual and overall quality is more optimized and more stable.

The high compression of this construction period is very important for Dehan's pile technology, which allows us to further develop other technologies in the future development (for example: DH 5th-order, 6th-order, 7th-order pile technology). This is a later story, and will talk about it later.

3. The application of DH quick piles in industrial construction

Traditional PC/PHC piles are commonly used in public/civil industrial buildings and workshops. The development and initiation of DH quick piles is also closely related to the construction of industrial buildings. This is mainly due to two aspects: safety and construction requirements (as detailed above).

3.1 Construction period: the shorter the better

The government is the owner of public works/project. Although there are time limits(period), the legal requirements, engineering progress, and ability of contractors will often make concessions on the designation of the construction period. The most common one is the most abundant construction period. In addition to the capital investment, the industrial construction that is more biased towards the private sector still requires the output of the product (the maintenance of profit and the production line). Therefore, in the construction process, the shorter the better. Moreover, due to the environmental disputes in Taiwan and the resistance of the residents, the construction of the project is also the sooner the better. Capital investment is the pressure of capital interest, product output is profit considerations, and the rapid establishment of the factory is the event of plant construction and the ability to quickly subsidize, so as to avoid other effects. In the decision-making of construction projects, there are often requirements for shorter construction periods.

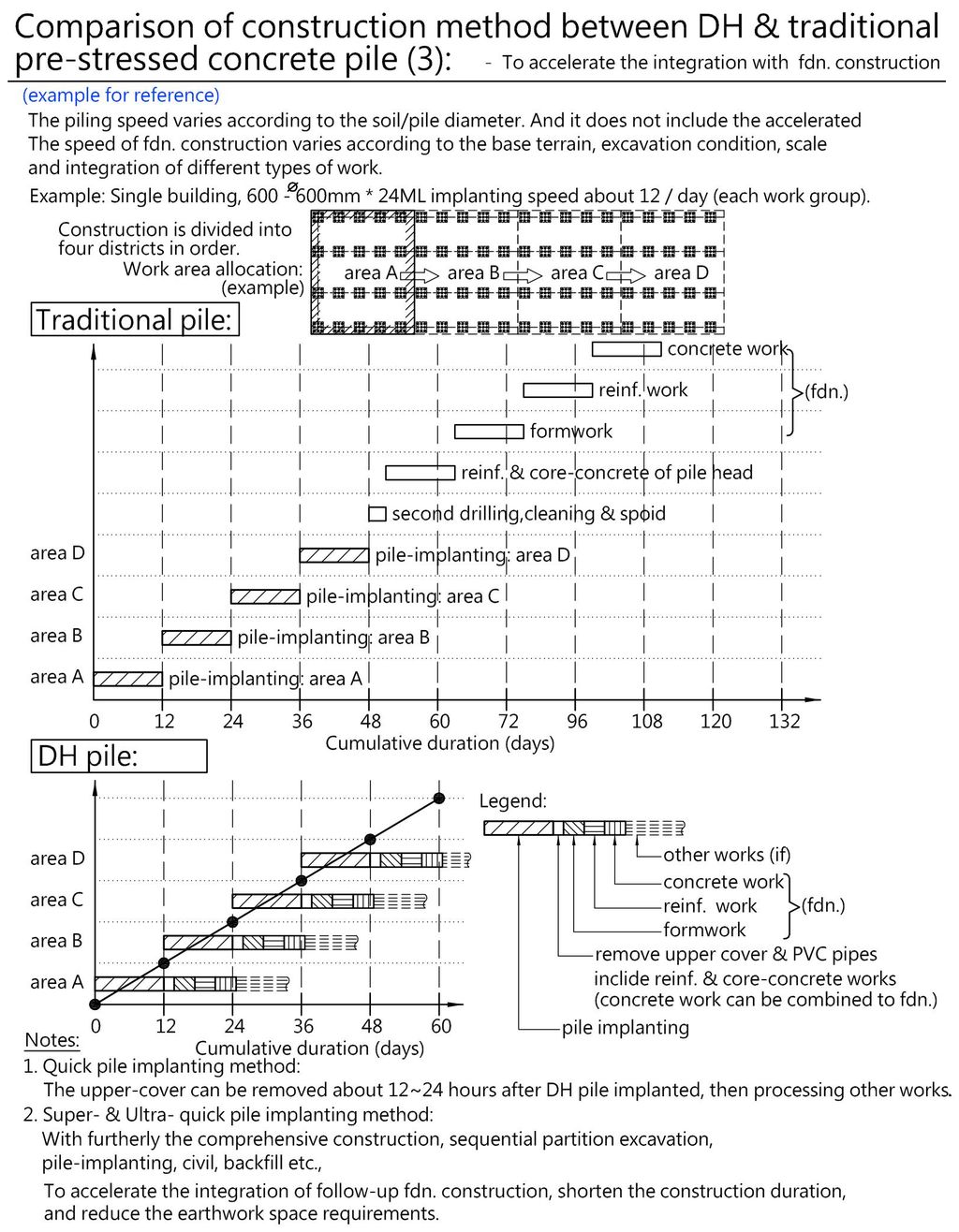

The construction speed of DH quick piles is fast (Fig. 1-8, Fig. 1-13). If the topographical geological and structural types of the case are suitable, and the integration of the types of work, the construction speed of the DH quick pile can be made faster (Fig. 1-14).

Use DH planting pile construction to move the site work as far as possible to the factory prefabrication (for example: hollow pile head) to shorten the construction time of the construction site, and also reduce the job interface and waiting time. This method is the best for industrial construction. the way. The use of PC/PHC piles is a common method in the industry, and DH quick piles are a further saving.

In Figure 1-14, it is commonly seen in long-span factory buildings, which are commonly found in manufacturing plants, such as petrochemical, steel, electronics, etc., when the district is implemented (A --> B --> C --> D) (subject to availability). If the site can be excavated first, the construction period will be better. It can be connected in series for each type of work, and the construction period is shortened.

In general construction, it is often mentioned that construction/continuous construction can be carried out immediately, but in most cases, in order to avoid unnecessary disputes or accounts, it is often waited until the previous package is completed. After completing or leaving the field, you will be allowed to pack into the work. This is the actual situation, so many construction periods can only be wasted in it; all the engineering language with continuous construction becomes a bubble.

The technology of DH quick pile: hollow pile head, preset horizontal reinforcement, immediate opening, immediate ribbing, and immediate grouting, which has achieved better quality, construction speed, and work type integration. The ideas have become concrete practices at your fingertips. When the time pressure of building a factory is greater, or the financing pressure is high, it will show the unique superiority of DH quick pile.

3.2 Quality: The better the better

As detailed above, we will not repeat them. The DH quick pile was made. 3.3 Inspection: the simpler the better

As detailed above, we will not repeat them. The DH quick pile was made.

3.4 Cost: The more you save the better Basically, DH quick piles, some parts (and labor) are added to the factory, and the cost will definitely increase. But this is only the cost of the factory, not the cost of the construction site. Considering the cost of other special processes during construction of the site, due to the special design of the DH quick pile itself (such as: reducing the secondary core/clearing process, no longer using expanded concrete, etc.), there is actually no increase.

When considering the huge contraction period caused by the reduction of the interface time of the job, the previous cost is not so important. This is also the most important technology for DH quick piles, not the hard steel reinforcement.

4. The conclusion

DH quick pile is the first pile technology developed by Dehan Company and has been improved to the 3rd generation. Dehan's DH quick pile is not only excellent in quality, stable, and short in construction period, it is worthy of your attention. The article written in this article is a bit longer, stinky, messy, and boasted, and some places have been repeated (a bit of muddy water), I hope you don't mind too much.

At present, Dehan Company defines DH quick piles (1st-level piles) as "industrial grade piles", while the 6th-level piles are " Turnkey-grade piles" and the 8th-level piles are " Consortium-level piles". After that, we will make more research and development, change, and more detailed introductions of PC/PHC piles, or you can pay attention to Dehan's official website (http://www.dehantech.com) or Facebook official website. (http://www.facebook.com/dehantech/), you can also write to us to discuss mutual growth.。 References:

[1] Yantong Engineering Co., Ltd. (2014), “Dehan Intellectual Technology Company: PC Pile Head Pulling Test Report”, Table 6-2, Kaohsiung City.

[2] Lee Shengnan (2016), “Improvement of pre-stressed pile head joints – taking the collapse of the Shanghai Building as an example”, Proceedings of the 2016 Asia-Pacific Urban Construction Practice Forum (Hong Kong), Hong Kong University of Science and Technology.

[3] Zhang Jiaqi, Liu Wenzong, et al. (2013), “Application of pile head treatment technology for DH-PHC piles”, Proceedings of the 3rd China International Pile and Deep Foundation Summit, pp.197~ 206, Shanghai, China.

[4] Lee Shengnan, Zhang Jiaqi, Liu Wenzong (2014), “The latest application of DH-PHC pipe pile technology in pipe pile joints and pile head joints”, Proceedings of the 4th China International Pile and Deep Foundation Summit, pp.111 ~123, Shanghai, China.

[5] Wang Chuanqi, Xu Jianyi, Xu Mingshan (1995), “Implanted Piles and Construction Quality Management”, Journal of Geotechnical Engineering, No. 52, pp.27~36, Taiwan.

[6] Wang Yuanjing, Kitazuki Koji, and Lin Zhenping (2007), “A case study of the design of the allowable wrap stress between the PFC pile wall and the poured concrete”, Proceedings of the 12th Geotechnical Engineering Symposium, A1-14, Taiwan.

File download: Official website download area: pdf file (Traditional Chinese version) (Simplified Chinese version) (Note: There will be some differences due to minor changes to the webpage text)

Technical inquiry: email: service@dehantech.com |