Case Study (5) - High Pressure Resistance Review of DH Quick-Bending

Lee Shengnan / Deputy General Manager of Dehan Intellectual Technology Co., Ltd.

date : 2017-10-29

Note: The readers shall know that most content of this paper is translated from original traditional chinese version by software.

Summary The plant's pipeline system provides the flow of pressurized fluid contents, which is a very important property that must be met by the pipeline system. This article will explore the implementation effectiveness and high pressure resistance review of Dehan's "Quick-Heavy-Cold-Pipe-Bending" technology (hereinafter referred to as DH Quick-Bending) by a recent implementation case. DH Quick-Bending technology is a kind of industrial piping operation that uses a lot of manpower. It uses a large-scale digital elbow processing machine developed by modern technology to carry out a large number of improved elbow joints to reduce costs and reduce construction time. Improve quality, reduce quality inspection load, reduce future maintenance, improve plant operation safety, improve fluid fluency in pipelines, and improve pressure resistance. Keywords: Quick-Heavy-Cold-Pipe-Bending, Quick-Bending, Dehan Forword In the previous case: "High Security Review of DH Quick-Bending" [2], we reviewed the high-pressure oil and gas pipelines in the case, caused by micro-damaged weld cracks in one of the hundreds of elbow ring-welded joints. In the actual case: "High-fluency review of DH Quick-Bending" [3], the inner wall surface of the process pipeline in the case was reviewed, and the process pressure loss caused by the weld bead protrusion welded by the ring mouth was missing. At the technical level of the DH Quick-Bending, the two problems frequently asked by the owner and the design unit are: the residual stress after cold bending, and the pressure resistance after cold bending. The former has been mentioned in the previous article [1] [2] [3], the latter is the subject of this article review by the case, in order to explain the Quick-Bending technology. In this paper, the two 1.25” sch.160 hydraulic pipes shown in Fig. 0-1 are used as the main body to illustrate the high pressure resistance (inner pressure) characteristics of the DH Quick-Bending. For easy reading, more photos will be explained to avoid essays and academics.

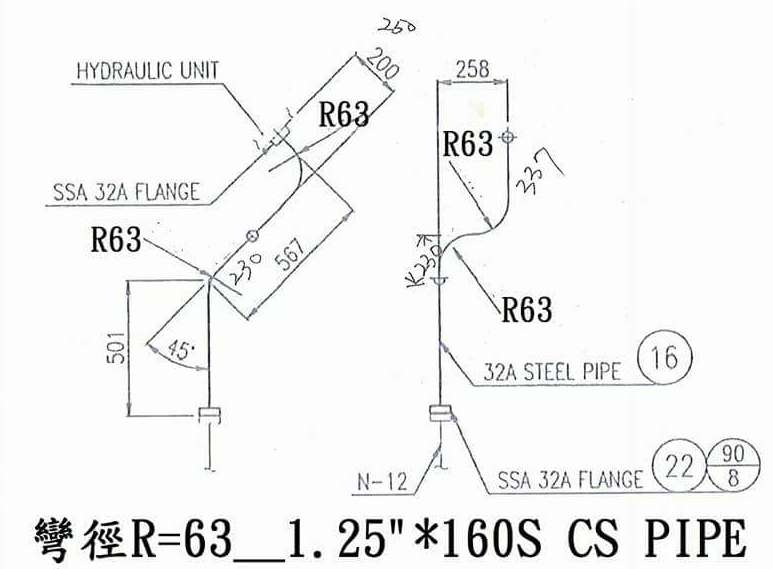

Fig. 0-1: 1.25” sch.160 pipeline

1. The traditional industrial piping method 1.1 How the traditional factory pipeline system works In the operation of the plant, the production material or the operating material must be transported from one end to another end by means of a pipeline, and the materials (the contents of the pipeline) are fluids, liquids, or powders, or mixed fluids, etc., Otherwise, it cannot flow in the pipeline. In order for these pipeline contents to flow, a pressure flow must be used, the most common way being pumping with a pump. (Note: This article takes the steel industry pipeline as an example, but mainly explains the petrochemical industry factory pipeline system) The production process has a certain amount of stable demand for the "supply amount" of the pipeline contents, and the pipeline contents must reach a specific flow speed within a certain period of time in order to meet the process reaction requirements. Using a simple fluid mechanics formula: Q=V*A, when the pipeline area (A) is fixed, to increase the flow rate (Q), it can only be treated by increasing the flow speed (V). To increase the flow speed, only the fluid pressure can be increased, so the factory pipeline fluid is mostly a pressure flow; of course, there are also a few gravity flows, such as some sewage drainage pipelines (Note: these are not the main pipeline types of the plant). The greater the pressure of the contents of the pipeline, the greater the pressure inside the pipe wall. The pressure inside these pipes is designed to be used as the basis for selecting the material, pipe diameter and grade (wall thickness). For pipelines of the same material, the greater the pressure, the greater the required wall thickness (the more expensive the price). The internal pressure of the general process fluid is still relatively small. If it is a fluid line for operation, such as a hydraulic pipe for mechanical operation, there is still a need for kinetic energy to push other equipment (such as a hydraulic cylinder or a brake). That is to say, in addition to the requirements of conveying flow, there is still a demand for conveying power, and the speed of fluid transfer is generally "super fast" in order to meet the needs of mechanical instantaneous operation. Therefore, the internal pressure of these hydraulic cylinders for mechanical operation will be very high, usually much higher than the pressure required for the factory process piping. For the pipeline system, the material strength of the pipeline and the wall thickness of the pipeline are higher. When the pipeline is subjected to a large fluid pressure in the pipe, it is usually designed with material strength and wall thickness. The material may be related to the physical properties of the pipeline contents. Sometimes it is required to have corrosion resistance, acid resistance and alkali resistance (such as SUS 304, 316, etc.), and the material strengths are different. The rest, it fell to the design of the "wall thickness". (Note: This article only talks about round pipes, not about square tubes) In the piping practice, the pipeline is not natural (or when rolling finished products) is a complete, curved and natural pipeline, but consists of many parts. In the traditional piping construction, these parts are roughly divided into pipes and elbows except for flanges. The pipeline system mainly combines many straight pipes and elbows and combines them into appropriate lengths and angles to reach the destination end from the source end in the three-dimensional space. These combined means have flange connections, and a small number of low-pressure systems (such as water pipes) can also be combined with male-female threads, but the most important way of joining is still to use welding called ring-welding. In short, it is to use the electrode as a medium to connect the pipelines on both sides (straight pipe or elbow). These welded joints are sometimes "straight pipe - straight pipe" type, mainly used in the extension of pipelines (the length of the pipeline is generally 6 meters long, there are rolling, transportation, metering considerations), it depends on the stack house, the consumption of materials (especially when special materials are used). Some joints are "straight pipe-elbow" types, which are the main subject of discussion in this paper.

1.2 joint types and weaknesses of "straight pipe - elbow" in traditional pipeline These "straight pipe-elbow" joint types are mainly used to change the direction of the pipeline. There are plane turns, vertical turns, and a combination of the two (three-dimensional). The angle is mostly 90°, followed by 45°. The turning angle can of course be other specified angles; however, the design work is indepedent. The piping construction is carried out on site, and it depends on the work space of workers. The angles is generally 90°, 45°. In piping construction, the more strange the angle is, the more "thick work" is, and the more expensive it is. Because the combination of "ring-welding" is work in high temperature (hundreds of degrees Celsius) to melt the electrode and the base metal, in addition to the weld bead itself is the weak point on the joint, the instant high-temperature welding will also make the base material produce material. Embrittlement, weakening, deterioration, and even cracks or sand holes (some related to the craftsmanship/proficiency of the welder), thereby it will reduce the internal pressure capacity of the original pipeline. The design is directly solved by "increasing the wall thickness"(choose another pipe size upward), that is, the pipeline level is adjusted one to two levels to deal with. These are actually letting the weakening factor on the material disappear naturally in the "increased wall thickness". 1.3 Elbow parts in traditional pipeline systems In the traditional elbow parts, except for the large-diameter elbows, which are made of multi-bend-pieces weld(mitres bend), the small-diameter elbows are mostly manufactured in the processing plant by high-frequency heating elbow type (see Fig. 1-1). It can be seen that the steel pipe (on the right side of the Fig.) is instantaneously heated to a high temperature of softening degree (partially and rapidly increase in temperature can be seen from the curved pipe of the red pass in the Fig.), expansion, bending, cutting, cooling (and rapid cooling?).

Fig. 1-1: Traditional elbows are manufactured by high-frequency heating in a processing plant (source: Youtube)

Fig. 1-2: Traditional elbows, packaging/transportation is quite time consuming [1] This high-frequency heating elbow processing has several characteristics: (1) A large amount of electrical energy is required. (energy consuming)

(2) The workplace is hot and the work is dangerous. (labor safety consideration)

(3) After the hot bending of elbow parts, the material will change in tension and extension for temperature, and then shall be cut and trimmed of secondary processing. Due to the high heat of the elbow, it must be reprocessed after the heat is removed.

(4) Only single elbow can be made, and usually a single 90° elbow type; if other angles (such as 45°) are required, it must be cut again (there may be material waste).

(5) After the elbow is completed at the processing plant, it will be packaged and transported to the prefabrication site assembly (see Fig. 1-2). The elbow parts factory belongs to another ordering, and the procedures of consolidation, purchase and preparation of materials, processing, quality inspection (which is questionable), packaging, transportation, etc. all require time/labor to work. It is no wonder that the construction period is lengthened.

(6) If the cooling process is too fast, there is still a high residual stress. (If the cooling rate is too slow, it will affect the factory operation time, space, equipment and manpower) The traditional piping contractor and elbow factory are different contractor. Usually, elbow parts packed in different manufacturers and to different locations, which is quite laborious (i.e. cost and duration). Don't miss-underestimate the packaging work, it is quite cumbersome for metal elbows, and is time-consuming and costly. When it transportation, the cost must increase. Sometimes, the elbow parts are purchased by the owner or the main contractor, and then the materials are transferred to the piping contractor for construction (shop or site), there will be a transfer/unpacking cost; the delivery is also time-consuming and labor-intensive, and the cost must be increased.

In the pipeline prefabrication, taking the 90° elbow as an example, both of the front and rear ends are welded with the straight pipe by the ring-weld joint [2][3], usually at least one end is prefabricated at the factory, and the other end may be shop prefabricated or site weld (may facilitate re-delivery to the site or installation) (see Fig. 1-3). (Note: Factory prefabricated depending on the location, may be in the piping factory(shop), or in the temporary site (field) set up near the construction site)

Fig. 1-3: Traditional elbows and straight pipes are welded by ring-weld joints (factory prefabricated) [1]

Fig. 1-4: Traditional elbow ring welds are more susceptible to cracking [1] The lack of traditional elbow ring- welding joint has been described in the previous article [1] [2] [3], that’s no longer speak. Before this new technology was developed, the only way to combine industrial pipe construction was the combination of ring-welding. (1) High temperature connection: The ring-welding can only be combined with high-strength electrode and steel pipe base material at a high temperature of more than several hundred degrees Celsius. The effect of high-temperature cauterization also destroys the base metal at the same time, making the material embrittlement, deterioration and weakening. (2) The weld is easily cracked: The welding of the ring joint adopts the method of full penetration welding. The electrode is easy to oxidize. The adjacent steel base material is also susceptible to oxidation due to the high temperature (because the material has been changed by high temperature). In the factory practice, the part of the ring-weld (which may be an electrode or a steel pipe) has always been prone to breakage, resulting in safety risks (see Fig. 1-4), mainly due to high temperature deterioration of the material. (3) A large number of professional welders must be used for ring-welding: Ring-welding is a full penetration welding method, which has many safety concerns (especially for petrochemical plants with explosive dangers), and even does not allow any sand holes at the weld bead. As long as the welder is doing the ring-welding, the professional "hand" stops for 0.5 seconds more or less, or shakes twice, or first smokes then continues welding, etc., will affect the weld quality. The difference (not every worker is "welding god"); sometimes the quality of the welding machine or age of machines will also have an impact to weld quality.

It is not to say that using of labor is not good, but manual work is likely to cause large variations in quality (may be affected by many factors such as weather/rain, mood swings, physical load, tools, safety protection, working space, training level, work experience, etc.). Taking the construction or maintenance of the petrochemical industry as an example, the pipeline welding workload is very high and the construction period is urgent. Many welders must be used, often working overtime, or even rushing through the night, which easily affects quality (risk). (4) Maintenance of the ring-weld joint is relatively difficult: The ring-weld joints of the elbows are mostly full penetration welds. Even if the surface of the weld bead is ground, it is not as smooth as the original steel pipe. In terms of coating rust prevention, it is inferior to the anti-corrosion effect of direct blasting and painting on the original surface of the steel pipe, which tends to increase the maintenance amount and increase the risk in the future (see Fig. 1-4). Taking petrochemical plant pipelines as an example, local factories have attached great importance to safety, but many pipelines in the plant are concentrated and staggered in high density. As long as there is a problem with a pipeline (such as leakage, combustion, explosion, etc.), it is possible Initiating a chain-type accident, burning for several days, or even burning the entire plant, the local case actually exists, and the responsibility for management risk is not small. 2. Case description Construction site: Kaohsiung City.

Construction classification: steel industry, terminal operation area.

Engineering nature: maintenance.

Special requirements: short construction period.

Use technology: Take Quick-Bending. 本文採用該案中的兩條管線來加以簡易闡述。

2.1 DH Quick-Bending can withstand huge pipe pressure

Fig. 2-1: 1.25” sch.160 (thickness 6.4t) hydraulic line (continuous 4 bends), ISO piping diagram

As shown in Fig. 2-1, it is a 1.25” sch.160 (6.4t thick) steel pipe, which is used in the hydraulic line of the dock unloader. The pressure inside the receiving pipe is set to 300 kg/cm2 or more. The purpose of taking these two pipelines as an example is to get rid of the superstitions of many people's consciousness. They always think that the curved part of the cold bending pipe become thinner because the metal pipe is stretched, the pipe wall is changed. And the possibility of danger of pipe cracking will increase. In practice, in terms of the above pipelines, the pressure required by the owner must be as high as 300 kg/cm2. For the expert, this is a fairly high pipe pressure, which is much higher than the pipe pressure required for the general petrochemical process line system. Of course, this pipeline is an operation pipeline, which is applied to the hydraulic pressure function. Under the requirement of instantaneous operation, the transmission pressure is high and the speed is fast, so there is such a high requirement. (Note: This sch.160 pipeline is quite difficult to see. Some industry workers may have never seen it in the whole life. The owner knows the points, and deliberately finds us.) The pipe pressure requirement of 300 kg/cm2 can meet the requirements, and other smaller pipe pressure requirements should be ok. This is probably not expected. If there are any dissidents, then it may be necessary to review it: Is it that the concept is too conservative, or that the company budget is too sloppy, the construction period is too loose, and the traditional piping method of old fashion is still used. We have all entered the 21st century, and we should let the industrial piping industry get rid of the labor-intensive style of industrial 2.0 production pattern, and should step into the ranks of "Industry 3.0". Unfortunately, now DH Quick-Bending still can't catch up the Industry 4.0. But we will continue to improve intelligent integration and aim to move towards Industry 4.0. I believe there should be opportunities. Of course, DH Quick-Bending have other advantages: (1) Low cost.

(2) Construction period is short.

(3) High precision.

(4) Strong pressure resistance.

(5) Less maintenance.

(6) Others, please consider it by yourself. This article uses this small section of high-pressure pipeline as an example to review, in fact, it is only a very simple statement, DH Quick-Bending can withstand huge pressure inside the pipe. 2.2 DH Quick-Bending test of pressure resistance In the inspection of curved pipes, we recommend two simple methods: (1) Wall thickness inspection: After direct straight pipe bending from the metal straight pipe, it can be directly tested (both online and offline). There are many types of thickness test instruments available for sale at the market; one of the thickness gauges currently used in our factory is the Dakota MX-3 Ultrasonic Thickness Gauge made in USA, which can be applied immediately (see Fig. 2-2). If customers have more precise requirements, they can also choose to send them to professional institutions for testing (such as SGS, MIRDC etc.) with credibility (the cost of inspection is inevitable). We know that, besides the first cooperation, professional test may not be necessary. The same machine, mold, and control program; this process is a reproducible program from a scientific point of view, ensuring that the same material, under the same procedure, can be repeatedly produced the same product. The same straight pipe material (There is not material to be steal, if the owner or the main contractor supplies material and control from the source.), the machine operation is fast, the construction period is not a problem, and it will catch up with your work. The quality of the pipe bends from the machine is almost the same, so I can't see what material shall be steal. However, if the customer wants to pay for the test, that will be good but spend more cost/time. It is better to go straight to the online inspection. We can also accept the client's entrustment, check the thickness on a piece-by-piece basis, and make the part history more complete; of course, the operating cost has to be added up (business consideration).

Fig. 2-2: Dakota MX-3 Ultrasonic Thickness Gauge mode in USA

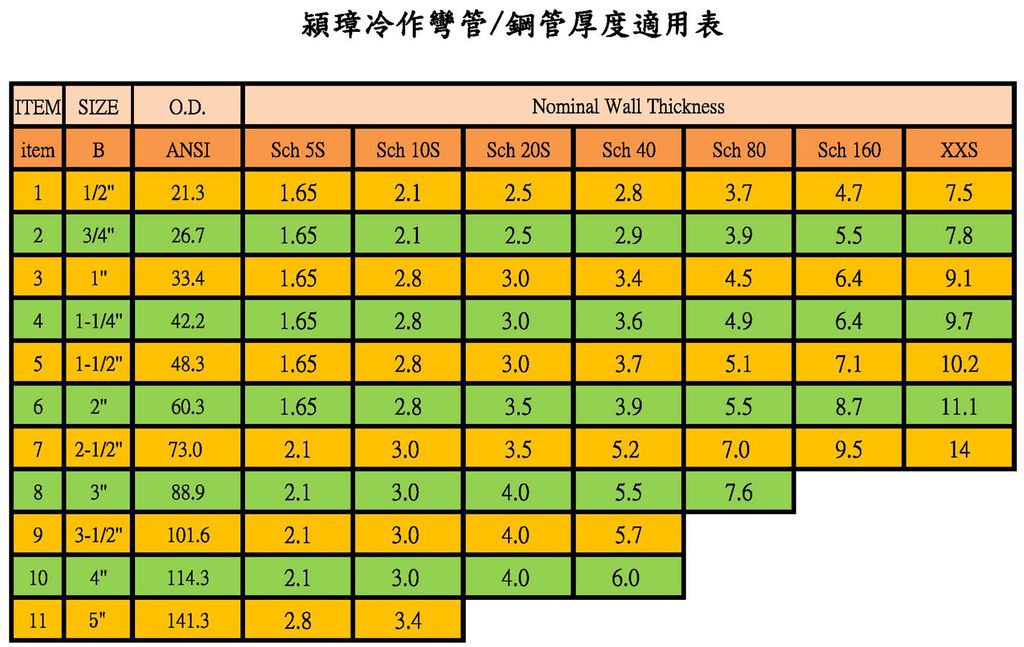

The Fig. 2-3 shows some of the DH Quick-Bending are suitable for steel pipes (variable depending on the material and grade). Fig. 2-4 shows the data of roundness and thinning rate (changes depending on material and grade) after DH Quick-Bending.

Fig. 2-3: DH Quick Bend Thickness Applicable Table (1/2" to 5" pipe size and grade)

Fig. 2-4: Recording roundness and thinning rate data after DH Quick-Bending (1/2" to 5" pipe)(The above table is part of the measured data, the correctness will be determined depending on the circumstances of the case) (2) Direct pressure test of pipe bends: Testing is the best way to ensure quality. The pressure test (commonly known as pressurization test) that must be carried out on finished products such as equipment or pressure vessels can be carried out by entrusting third-party inspections (such as the Industrial Safety and Health Associations) to practice the reliability of quality inspection. The finished pipeline can also be verified by a similar pressure test, which is one of the most reliable quality inspection methods. We can carry out some simple specific water pressure test on specific pipe diameter in our factory (sorry, the equipment in the factory is limited, the inspection is not our profession), which can meet some of the needs of customers. Of course, customers who require higher and more rigorous results can still send pipe bends to third-party inspections. In the same way, cost and time will increase. 2.3 DH Quick-Bending pipe is very suitable for petrochemical pipeline As shown in Fig. 2-5, for another real case, the comparison between the traditional elbow used in the petrochemical plant and the DH Quick-Bending. The pipeline material is 2” sch.160 SUS304 grade, which belongs to thick pipeline, high internal pressure and high acid/alkali resistance. It is generally used in process pipelines in petrochemical plants. In the upper right Fig. of the Fig. 2-5, the difference between the traditional elbow and the DH Quick-Bending can be clearly seen. It is not necessary to wait for the elbow material, directly bend the pipe, and after bending the pipe, the pipe bend can be designed to be welded on the extended straight pipe (under the same conditions, the "straight pipe-straight pipe" weld bead is more than the "straight pipe-elbow" The quality of the weld bead is much better. It saves material loss and, more importantly, saves a lot of manpower and saves a lot of construction time.

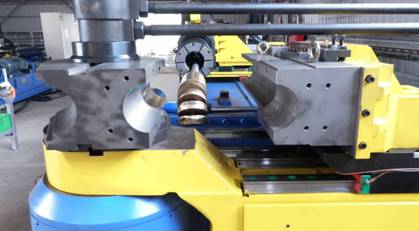

Fig. 2-5: Comparison of traditional elbows and DH pipe bends of 2” sch.160 SUS304 There are many kinds of pipelines in the petrochemical industry. The materials, pipe diameters and grades vary greatly. It is inconvenient to give an example. In the above picture, we use photos in comparison to make a simple explanation. The petrochemical industry has higher risks, and the owners are generally conservative. Engineers engaged in professional pipeline design are also more cautious. In the traditional pipeline system, taking elbow parts as an example, the damage occurs mostly in the weld bead of ring-welding (and the adjacent steel pipe base material), rarely occurs in the elbow body and the straight pipe. The reason is mainly due to high temperature welding, which destroys the original material. The traditional pipeline system must be connected by means of a "straight pipe - elbow - straight pipe" to complete the overall system configuration. Direct bending has actually been available for many years, but why not accept it for the petrochemical industry? The reason is that the previous bending tools (and molds, etc.) are not progressing enough, the output is insufficient, the precision is low, the quality control pipe can not meet the requirements, and only some thin pipes (such as handrails) can be bent, and the safety/quality is not emphasized. Nowadays, DH Quick-Bending technology has emerged. With the more modern digital bending machine, more force output, higher precision, faster work speed and better quality have been able to meet the demands of all kinds of pipe bends, especially It can meet the needs of heavy industrial piping (such as petrochemical industry, steel industry, etc.) and is better. (See Fig. 2-6)

Fig. 2-6: Digital Bending Machine for DH Quick-Bending The traditional pipeline system must rely entirely on the "straight pipe-elbow-straight pipe" ring- welding joint method, which is time-consuming, labor-intensive, wasteful of materials, and many inspections. In short word, the cost is high, the construction period is long, and the quality is poor. Due to the emergence of DH Quick-Bending technology, the traditional joint method has been changed a lot (still not 100% free of ring-welding work, but the number can be greatly reduced), which can quickly upgrade the local industrial piping project. 3. Conclusion The four points in para. 1.2 above have been noted in the previous article [1][2][3]. The reason for repeating the statement here is mainly for the purpose of this article: Corresponding to "DH Quick-Bending pressure resistance". As the above, we know that in the case of petrochemical piping, the damage control management of the pressure inside the pipe mainly comes from the destruction of the ring-weld bead and the base material of the ring-weld, but it has not relationship with the thinning of the pipe bends itself. In order to overcome the lack of these ring-welds, the pipeline system was designed to eliminate defects by thickening and upgrading. DH Quick-Bending pipe is a direct cold bending pipe. The bending process is controlled by high-precision guiding mold. With the precise control of the digital program, basically, the DH pipe bend itself is uniform in material and uniform in wall thickness. Smooth pipe bends, no abrupt damage points (such as weld sand holes, cracks, etc.), there is less loss in the pressure inside the pipe. In the case of standard pipelines, the pressure inside the pipe can withstand much more than the pressure requirements of the pipeline contents. In addition to the special requirements of art, in industrial production, manual control of product quality and precision control is far less than mechanical control, especially after adding digital control (CNC) mechanism. If you are in long-term work (such as 24HR or urgency work), the mechanical work is on standby, the accuracy depends on the guided mold fixture and program control. The manual work can only work in 3 to 4 shifts (cost is amazingly high, the quality of the product is amazingly low), and its efficiency, precision (quality), and even work safety can not catch up with machines. The local labor policy and legal regulations are also becoming more rigorous, and it is inevitable to lean toward the labor side, and it is also an ongoing trend among various industrial countries in the world. The DH Quick-Bending technology is honed in decades of work experience, pursuing the optimization of cost, quality, speed and inspection. The traditional industrial piping industry is neither a service industry nor a manufacturing industry, but an engineering industry. The introduction of DH Quick-Bending technology is to re-regulate the work of the industrial piping industry more like manufacturing, such as factorization, standardization, and process, replacing expensive manpower operations cost with newer, larger pipe bending machines. Pursue higher yields. References:

[1] Lee Shengnan (2017), “Introduction to DH Quick-Heavy-Cold-Pipe-Bending Technology”, Dehan Company, Taiwan.

[2] Lee Shengnan (2017), “High Security Review of DH Quick-Bending”, Dehan Company, Taiwan.

[3] Lee Shengnan (2017), “High-fluency review of DH Quick-Bending”, Dehan Company, Taiwan.

File download: PDF file - (Traditional Chinese version) (Simplified Chinese version) (English version)

(Note: There may be some differences between the text and the web version)

Technical inquiry: email: service@dehantech.com

Production Factory: Ying Zhang Industry Co., Ltd. – Web , Facebook

Postscript: - In the industrial piping project, the pipeline is not allowed to have any "fracture" or even "micro-crack", because this will cause great safety incidents. Many people's perception of "pipe bends" is still the impression of "pipe bending" in the last century, as if the pipeline is most vulnerable to damage from this bent pipe. In fact, it is true that the strength of the "bent pipe" is inferior to the "straight pipe". However, in practice, "elbow ring-welding" is worse than "bent pipe", and the safety of the work is greater (higher risk). The reason why "elbow ring-welding" is also applied in pipeline design and construction has two main reasons: (1) because there is no better solution until the end of the 20th century. That is: If you don't use it, you don’t have any solutions. (2) In design work, a lot of safety factor has been added to the elbow ring-weld, which is enough to cover the missing, unless ..... (There are many factors, mainly in the artificial face).

The emergence of DH Quick-Bending is to solve these two difficulties. (update @2017-11-07) |